There are many ways to print patterns on school uniforms, including screen printing, thermal transfer, digital direct injection and embroidery. In general, different printing techniques and methods will have different effects. The following describes the printing patterns on clothes Methods:

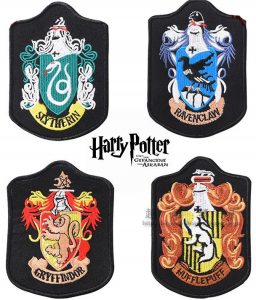

1. Embroidery

Embroidery is the general term for various decorative patterns embroidered by needles and threads on fabrics. Embroidery is divided into silk embroidery and feather embroidery. It is to use needles to pierce silk threads or other fibers and yarns on the embroidery materials with a certain pattern and color to embroider A decorative fabric composed of traces. It is an art that uses needles and threads to add human design and production to any existing fabric. Embroidery is one of the traditional Chinese folk handicrafts and has a history of at least two to three thousand years in China. There are four main categories of Chinese embroidery: Suzhou embroidery, Hunan embroidery, Shu embroidery and Guangdong embroidery. Embroidery techniques include: wrong stitch embroidery, random stitch embroidery, net embroidery, full-floor embroidery, lock silk, nasi, najin, flat gold, and shadow gold. The use of embroidery mainly includes life and art decoration, such as clothing, bedding, tablecloth, stage, and art decoration.

2. Screen printing

Screen printing technology is rumored to have appeared as early as more than 2,000 years ago and originated in China. Screen printing belongs to stencil printing. During printing, the ink is transferred to the clothes through the mesh of the graphic part through the squeeze of the squeegee. Form the same image and text as the original. When printing, the screen frame is first prepared, where there are patterns in the screen frame, where there are hollow meshes, and the meshes where there are no patterns are smeared. When printing, the color paste is scraped through the mesh and printed on the clothes. You can make as many screen frames as there are colors, and put them on one by one.

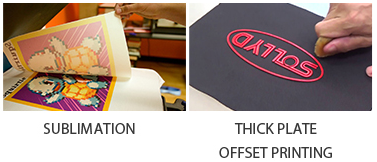

3. Heat transfer printing

The main principle of thermal transfer printing is to sublime the ink on the paper to the fabric through high temperature and high pressure. It is mainly used for polyester fabrics. The color of the fabric is mainly white, but light colors are also acceptable. Pure cotton fabrics are not suitable for sublimation. Because pure cotton fabric does not absorb ink, and the temperature is high when it is heated, the temperature has a great influence on the cotton cloth surface, not only the color of the cloth surface, but also the shrinkage rate and so on.

4. Digital direct-injection printing

Digital direct-injection printing simply means that the image or source file is directly input to the computer through various digital means, such as scanners, digital cameras, etc., and the required files are formed after editing and modification through the printing software system, and then controlled by the dedicated RIP software. The direct-jet printing machine sprays ink (paint, active, acid, dispersion) through the nozzle directly onto the clothes as needed, and then undergoes post-processing to obtain clothes with high-precision patterns.

Various Printing Process for your reference